Tolerance Analysis

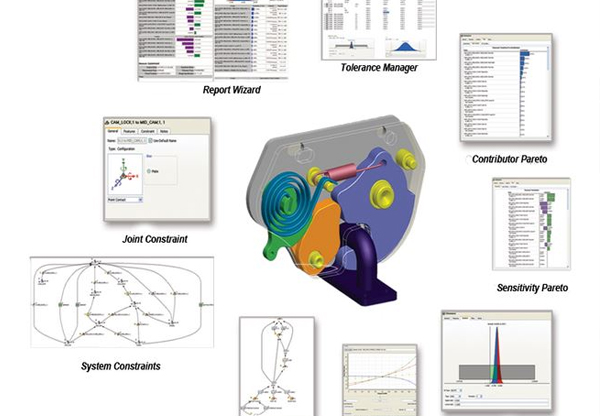

Tolerance Analysis is one of the areas of manufacturing engineering, related to the study of accumulated variation in mechanical parts and assemblies. Such techniques can be used in mechanical and electrical systems to measure subjected to accumulated variations.

With our Tolerance Analysis Services, we can help you properly tolerance your drawings and to analyze the tolerances applied to your designs from the bottom up or from the top down. We can also analyze your clients’ and suppliers’ drawings, making sure the specifications they have proposed will work and satisfy your needs, or to determine if there is a mistake or tolerancing problem on their drawings.

Development of G D & T Drawings per ASME Y 14.5 / ISO Standards

Stack-Up Analysis

Conversion of Plus/ Minus Toleranced Drawings to G D & T Drawings

1-D, 2-D and 3-D tolerance stack up analysis to predict Assembly Build and Performance

Worst Case Tolerance Analysis with Inteference Check for predicting Build Issues

Least Cost Tolerancing of parts to protect assembly build and function based on Process Capability available in the Organization

Optimization of Tolerances for Least-Cost

Sensitivity Analysis of Tolerances for specified objectives in Assembly and Performance

Specification of Inspection Dimensions for Quality Control